Metallized Film Services

Our Capabilities

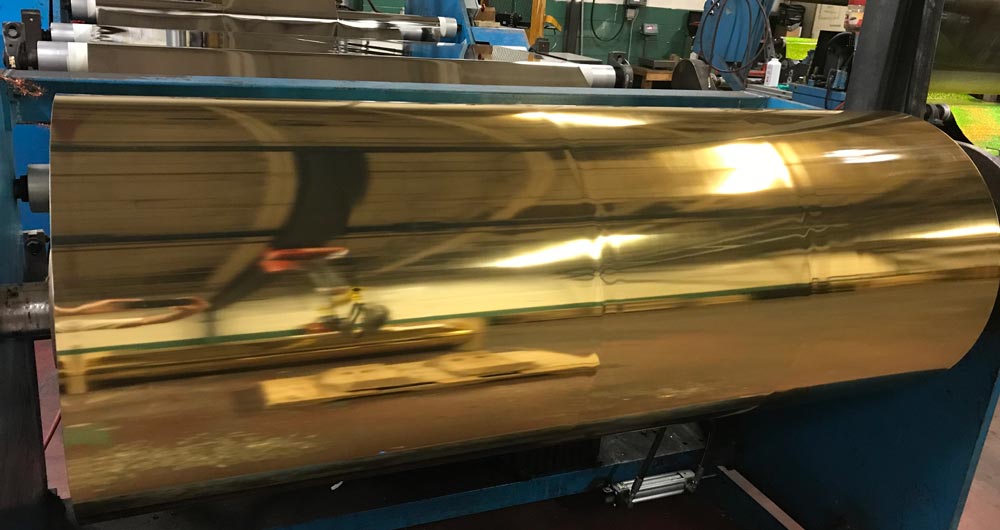

If you’re looking for metallized materials for decorative or packaging products, our state-of-the-art vacuum metalizing services can deliver.

We have offered custom vacuum metallization for many years and have the capability to create a wide range of sizes on a variety of substrate materials.

At our large manufacturing facility, we can vacuum metallize rolls with widths up to 66”. Our metallizing machinery can handle rolls with cores of 3”, 6” or 10” and diameters up to 32”.

We can produce metallized films ranging in thickness between .00036” to .040” (0.36 – 40mil).

Available Materials

We can offer a wide range of colored metallized finishes and we can customize to suit your needs.

- Polyester (PET) and Amorphous Polyester (APET, RPET, PETG)

- Aluminum Foil

- Polypropylene (OPP)

- Rigid Polyvinylchloride (PVC)

- Polyethylene (PE)

- Foamed Polypropylene (FPP)

- Polystyrene (OPS)

- Mearl (Iridescent)

- Paper and Board stock

The Metallized Film Manufacturing Process

To metallize film, a process of vacuum coating takes place, which adds a thin layer of aluminium or other metal coating to a substrate material. This results in a uniform, flat metallized layer.

Our vaccum metalizing services include a process that begins with evaporating the coating metal in a vacuum chamber, then applying it to the substrate web as it is passed through a small gap in the machine. The coating condenses on the material, creating a metallized finish.

Vacuum metallizing is sometimes referred to as ‘Thermal Evaporation’ metallizing or Physical Vapor Deposition (PVD). It is the most common process for applying metal alloys to a substrate material.

It is used primarily in the decorative and packaging industries for items such as streamers, ribbons, beer labels etc.

Get a Free Quote on Vacuum Metallizing

Or call our office at (203) 792-0034 to speak with someone from our team.